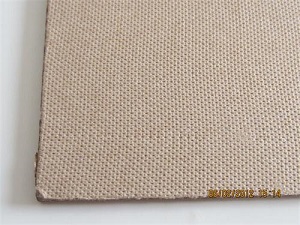

Transformer Presspaper:

It is made from 100% Unbleached sulphate wood-pulp. Cardboard makes which on the intermittent type board machine .Its characteristic is: Material free of strain,very flat , thickness even, the surface smooth, the mechanical strength high, has the obdurability and the electric insulation . Used in oil-cooled power transformers and distribution transformers primarily due to their high purity, mechanical strength and optimal oil-impregnability. The components formed of pressboard, such as angle rings, snout segments and end leads, enable an exact adaptation to the electric field conditions prevailing in the transformer. Pack :sheet size:1000X2000mm、1400X1100mm、1400X2000mm, Color:red ,green,Nature Thickness:0.10,0.13,0.18,0.25,0.38,0.50,0.80,1.00,1.60,2.00,2.50,3.00.4.00mm

PI2(Coil Insulating Paper Class2):Thickness 0.03,0.04,0.05,0.06,0.075,0.08,0.09,0.10,0.13,0.18,0.25,0.38mm

Heat Resistant Papert for Insulating "HPI-Green":Thickness 0.05 , 0.075 , 0.08mm

Special sizes and thicknesses upon request , process insulation compenents for construction part and Hand-moulded special shape Components as:End Ring ,Clamping Ring ,Bushing,Tubes,Fan-angle,insulating Angle Caps etcs.products through ISO 9001.UL,SGS certification.

Application:

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

China Public Security No.41120202000021号

China Public Security No.41120202000021号